Production

Acti-Med carries out the following production processes

- Grinding of cannulas

- Spraying plastic parts

- Assembly of cannulas and plastic parts

- Packaging

- Sterilization

Needles

For the many different applications and possibilities we offer you an assortment of different types of tips and cuts.

|

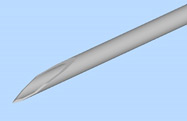

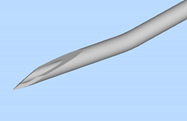

Lancet PointStandard tip design – very good – time tested. |

|

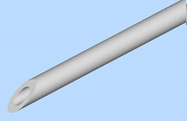

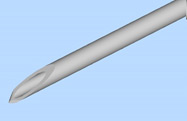

Single BevelThis tip is perfected with a strong Anti-coring treatment and is primarily used for the piercing of rubber stoppers. |

|

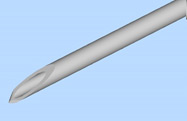

V-BevelThis type is similar to the Lancet Point but with five cutting surfaces and more material, thereby providing a more stable tip. |

|

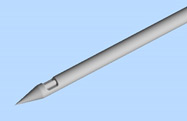

Pencil PointThis cut can be classified as anticoring. The inflow or outflow is achieved through a side hole. This tip is usually used for spinal anesthesia. |

|

Huber Tipground surface onto a level with the tubing. Anti-coring effect when piercing a silicone membrane. Minimal discomfort during skin penetration. Suitable for filling ports. |

|

Quincke BevelA fine, sharp, spinal needle that can be supplied with a stainless steel stylet and plastic hub. |

Packaging

Acti-Med packages its finished products in blister packaging, cans, or in bulk.

The printing is individually customized to suit the customer's needs. For special customer requests, we can also plan and develop a custom packaging solution.

Sterilisation

Acti-Med offers medical devices in all stages of production.

From stainless steel cannulas via assembled products to packaged sterile products. Acti-Med sterilizes at qualified sterilization companies. We are therefore able to offer both ETO and gamma sterilization.

Cleanliness

Acti-Med has a novel cleaning system that has been validated for cleaning all needle sizes.

The cleaned needles (mainly for prefillable disposable syringes) are processed and / or packaged in ISO class 8 (100,000) cleanrooms. Our cleanrooms have a very low particle count and are regularly tested according to ISO 7864 for acidity / alkalinity and extractable metals.

Top Quality

Acti-Med pays special attention to insuring the highest quality of cannula tips.

Care is taken during the entire cannula production process and during the cannula assembly to ensure that the tips remain as untouched as possible. Should it come to a contact (for example, for precise length adjustment when gluing), the needles are scrutinized as part of a process validation - to ensure optimum, consistent quality.

During cannulation, the finished, clean cannulas are 100% controlled for tip damage / incompleteness, and for the presence of particles and burrs. The Editio Cantor error rating list for disposable syringes and cannulas is used, which is the industry standard for high-quality cannulas.