Product development

Planning

We can take care of the planning and development and you will receive certified, high quality products!

For specific customer requests and / or special requirements, we will gladly work with you to develop individual solutions.

You provide the vision and framework and together with Acti-Med we will further develop the idea and create the desired product.

Development

There are many different requirements for the products, the production, and the documentation.

- A cannula is not always intended for injection into a body ...

- A cannula does not always have only two holes ...

- The standard treatment of cannulas is not always correct ...

- Needles do not always have just one tip …

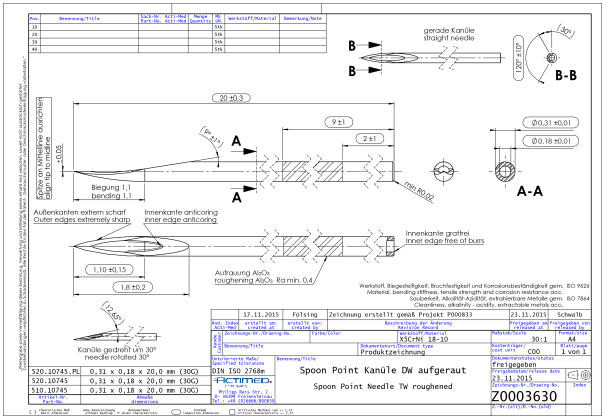

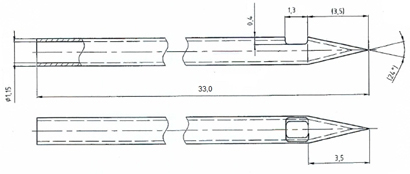

We do not always receive well designed drawings with the requests.

Sometimes we just get a sketch:

Do you know exactly what you want or do you only have a few key details?

Can you tell us:

- the purpose / scope?

- • the materials to be used?

- • the shape of the desired products.?

Thereafter,in close cooperation with Acti-Med, the preparation of a specification is carried out in order to produce your perfectly tailored product in the required quantities.

Your product requirements are always at the forefront of Acti-Med goals.

In addition to Acti-Med's manufacturing sites (in Poland and Germany) Acti-Med also has access to a large network of professional suppliers and partner companies.

We are always happy to produce a series of samples during the project phase in order to fine-tune the subtleties of the specification in relation to the customer's desired end product.

Examples:

You need a cannula that can be produced in the size 22G (0.7 mm) - 20G (0.9 mm).

The exact diameter has not yet been determined …

We produce samples in various diameters that you can use for experimental purposes.

Corrosion resistance is important to you …

We suggest a material to you that can guarantee corrosion resistance in connection with the drug used.

You need a cannula that is inserted into an autoinjector and used to pierce through a rubber stopper ... We suggest you a suitable tip shape, which is low-punching and has a low puncture force at high speeds.

These examples describe the basis for just a few of many possible implementations. Whatever you need, we can design together and turn it into a top product.

Clearly defined processes enable the reproducibility and transparency of processes.

Once your product is defined, it's about how it can be optimally produced.

Whether you need smaller quantities from a manual assembly process - or millions of cannulas from a facility with validated machinery - we design the right process for your product.

Our technicians have access to all development and sample production tools.

From ordering the right tubing, to planning the individual process steps, to drawing up inspection plans or defining in-process controls – you can rely on our considerable experience.

We're always working to advance the production process for a variety of cannula types, increase the performance of existing processes, and replace slow, manual processes with faster, more productive, automated solutions.

We work together with mainly german mechanical engineers, who helps us to fulfill your special conditions.